Plastic 3D Printing

1 to 500+ parts

Delivery times as fast as 10 days

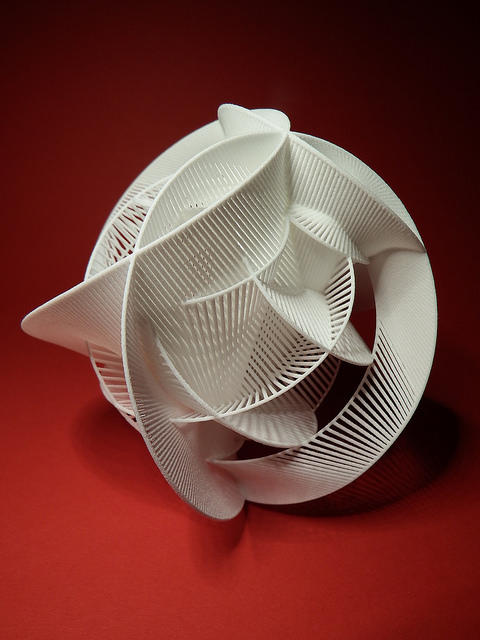

Stereolithography (SLA)

SLA prototyping is one of the earliest 3D printing methods. It uses a UV light to cure a photopolymer, such as ABS, layer-by-layer, making a durable plastic solid with good resolution of detail. SLA is typically not fast but it wastes little material, and the prototype can be used “as is” or as a master mold for a polyurethane vacuum casting.

Selective Laser Sintering (SLS)

SLS prototyping uses a laser to fuse powdered Nylon into a physical solid layer-by-layer. The process makes a prototype with a rougher surface texture that requires secondary finishing if it’s to be used as a master mold, but the advantage is that the prototype is more robust than its SLA counterpart, making it more suitable for mechanical models.

Fused Deposition Modeling (FDM)

In FDM, a thermoplastic filament is heated to its melting point and then extruded, layer by layer, to create a three dimensional object.

Materials

ABS, PLA, PETG, Nylon, Taulman, Flex

Build Size

We have the ability to do large scale prints

up to 590 x 600 x 600 mm / 23.2 x 24 x 24 in.