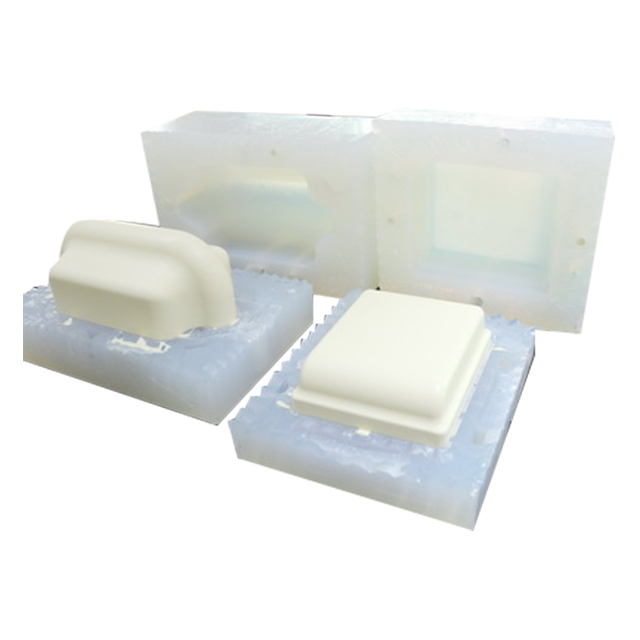

Polyurethane Vacuum Casting

1 to 50+ parts

Delivery time as fast as 10 days

Variety of painting and finishing options available

Tolerances

The finished dimensions of vacuum cast parts is dependent on the accuracy of the master model, part geometry and casting material. In general, a shrinkage rate of + 0.15% is to be expected. Oversized parts can be post-machined as required.

Advantages of Vacuum Casting

Polyurethane vacuum casting makes high-quality finished parts that are nearly the equal of injection molded pieces, without incuring the related cost. The silicone mold lends itself well to replicating complex features and overhangs that would be difficult to 3D print, and the surface can be refined to produce a high-gloss clear acrylic finish. It is even possible to overmold dissimilar materials or threaded inserts. The disadvantage is that the silicone mold is not durable and cannot be relied upon to make more than approximately fifty pieces, depending on part geometry.